How can we solve those problems ? Various damage modes of bearings .

Bearing in operation can not be directly observed, air compressor maintenance engineers through noise, vibration, temperature, lubricant consumption and other conditions can detect abnormal bearing. Timely check and analyze the cause of failure to avoid greater loss. The following is the cause of bearing failure. Most customers of our company take preventive measures in advance in the guidance and feedback of our maintenance engineers.

Air compressor bearing

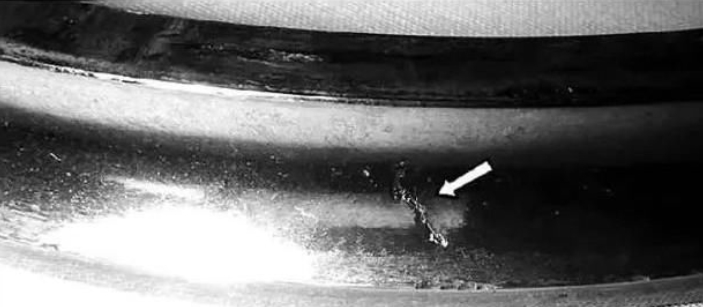

1. Crack defect

Some of the gaps are cracked.

Reason: the impact load of the main engine is too large, and the interference between the spindle and the bearing is too large;There are also large peel friction caused by cracks;Poor installation accuracy;Improper use (with copper hammer, stuck in large foreign body) and friction crack.

Solution: should check the operating conditions, set appropriate interference and check the material, improve the installation and use method, check the air compressor lubricant to prevent friction cracks.

2. Metal stripping on raceway surface

Operating surface stripping.After peeling, it was obviously concave and convex.

Reason: bearing rolling body and inner and outer ring raceway surface are subjected to periodic pulsating load, resulting in periodic change of contact stress.When the number of stress cycles reaches a certain value, fatigue stripping occurs on the rolling body or inner and outer ring raceway work surface.This fatigue is aggravated by excessive bearing load.In addition, improper bearing installation, shaft bending will also produce raceway stripping phenomenon.

Solution: the working conditions and choice of bearing and clearance should be restudied, and the machining accuracy, installation method, lubricant and lubrication method of shaft and bearing box should be checked.

Air compressor accessories

3, rust corrosion

.png)

Partial or all of the surface rust, rolling body variation strip rust.

Cause: improper storage, improper packaging, insufficient anti-rust agent, moisture and acid solvent invasion, direct use of hand bearing.Invasion of water, corrosive substances (paint, gas, etc.).The lubricant is not suitable.Water droplets are attached to water vapor by condensation.Stop running when it's hot and wet.Poor rust protection during transportation.

Solution: to prevent rust in storage, periodically or irregularly re-oiling packaging, strengthen sealing performance, regular inspection of lubricating oil, oil quality unqualified or deterioration to timely replacement, to the correct use of bearings.

4. The cage is broken

Rivet loose or broken, rolling body broken.

Reason: excessive torque load, insufficient lubrication, frequent rotation speed change, large vibration, bearing installed in the inclined state, stuck foreign matter.

Solution: to find out whether the operating conditions and lubrication state is appropriate, pay attention to the use of bearing, study whether the selection of cage is appropriate and whether the bearing box rigid load requirements.

5, creep

Inside diameter or outside diameter surface slip, causing mirror or discoloration, sometimes stuck.

Reasons: insufficient interference at the fitting place, insufficient sleeve fastening, abnormal temperature rise, excessive host load, etc.

Solution: to re-study the interference amount is appropriate, check the operating conditions, check the accuracy of the shaft and bearing box.

6, burns

The bearings become hot and discolored, thus burning and unable to rotate.

Reasons: generally insufficient lubrication, lubricating oil quality does not meet the requirements or deterioration, and bearing assembly is too tight.In addition, the clearance is too small and the load is too large (pre-loading large), roller deflection.

Solution: select appropriate clearance (or increase clearance), check the type of lubricant, ensure the injection amount, check the operating conditions, to prevent positioning errors, improve the bearing assembly method.

7. Bearing indentation

Damage condition: indentation on raceway surface or rotational surface caused by biting into metal powder, foreign body, etc.As a result of the impact of the installation, the rolling body in the distance between the formation of concave (brinell indentation).

Cause: metal powder and other foreign bodies bite into.Excessive shock load during assembly or transportation.

Solution: impact shaft sleeve.Improve sealing device.Filter lubricating oil.Improve assembly and usage.

8. Bearing wear

Damage status: the so-called wear is caused by friction raceway surface or rolling surface, roller end surface, shaft ring surface and cage concave wear.

Cause: foreign body invasion;Development caused by electric corrosion of rust;Poor lubrication;Skidding caused by the irregular movement of a rolling body.

Solution: improve the sealing device;Clean the bearing box;Fully filter lubricating oil;Check lubricant and lubrication method.

9. Bearing discoloration

Damage status: due to temperature rise and lubricant reaction, raceway wheel and roller and cage change color.

Reason: poor lubrication.The reaction with the lubricant results in hot immersion.The temperature goes up a lot.

Solution: improve the lubrication method, change the air compressor oil.

10. Bearing burns

Damage condition: raceway wheel, rolling body and cage heat up rapidly in rotation until discoloration, softening, deposition and breakage.

Reason: poor lubrication.Too much load (too much pre-loading).Too fast.The clearance is too small.Invasion of water and foreign bodies.Poor accuracy of shaft and bearing box, large deflection of shaft.

Solution: study lubricant and lubrication method.Correct bearing selection.Study the fit, bearing clearance and preloading.Improve sealing device.Check shaft and bearing box for accuracy.Improve installation methods.

11, bearing false burt indentation

Damage state: during microvibration, the contact part of the rolling body and the raceway wheel develops wear and tear due to vibration and shaking, resulting in an impression similar to brinell's indentation.

Reason: in the process of transportation, the vibration and swing of the bearing when it stops.Oscillating motion with small amplitude.Poor lubrication.

Solution: the shaft and bearing box should be fixed during transportation.The inner and outer rings should be packed separately for transportation.Plus preloading reduces vibration.Use a proper lubricant.

Skype

Skype